Çözümler

Horse Construction, teknik destekler, dokümantasyon destekleri, ürün destekleri, yazılım destekleri, proje destekleri ile tam bir yapısal güçlendirme malzemesi yelpazesi sunar.

Yapısal Güçlendirme İçin CFRP Gereksinimleri

Yapısal takviye talebi artmaya devam ettikçe ve CFRP'nin yüksek mukavemet, ince kalınlık, hafif ağırlık ve korozyon direnci özelliklerine sahip olduğundan, CFRP, yapısal takviye alanında yeni bir gelişmiş takviye malzemesidir. Peki CFRP takviye inşaatında ne yapılması gerekiyor?

1. CFRP takviyesi muayenesi ve anketinde iyi bir iş yapın

CFRP takviye inşaatından önce, CFRP takviye inşaat sahasını incelemek ve incelemek gerekir. Sadece CFRP takviye sitesinin sorunlarını tam olarak anlayarak daha kapsamlı bir CFRP takviye tasarımı ve inşaat planı formüle edilebilir.

2. Yetkili bir takviye şirketi seçin

Farklı takviye şirketleri farklı takviye inşaat kalitesini garanti edebilir. Profesyonel takviye şirketleri sadece profesyonel bir takviye tasarım ekibi değil, aynı zamanda profesyonel bir takviye inşaat ekibi de var. Böyle bir takviye şirketi takviye inşaatının kalitesini sağlayabilir ve sahibi de daha endişesiz.

3. Kalifiye CFRP yapıştırıcı seçin

CFRP yapışkanının kalitesi, CFRP takviye yapısının etkisini doğrudan etkileyebilir. CFRP takviyesi için sahte yapıştırıcılar seçilirse, CFRP takviyesinin yapısal etkisi gereksinimleri karşılamamalıdır. Bu nedenle, CFRP takviyesi kullanıldığında, kaliteli bir yapıştırıcı seçilmelidir ve tüm göstergeler ve performanslar CFRP takviyesinin standartlarını ve özelliklerini karşılayabilir.

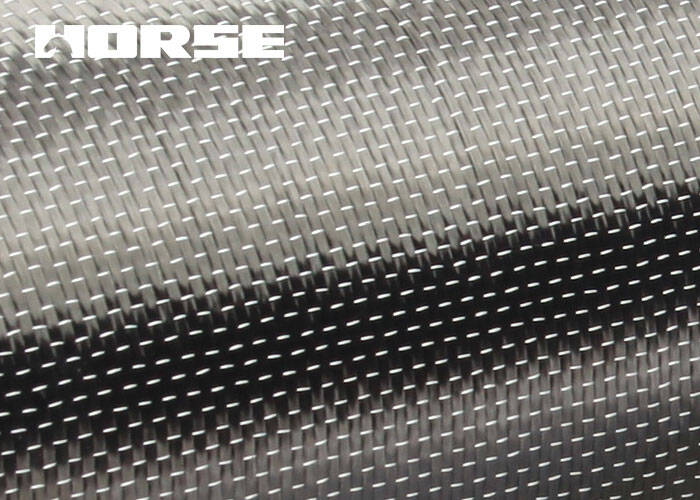

4. Yüksek kaliteli CFRP kumaş seçin

Şu anda, pazardaki CFRP kumaş karıştırılmıştır. CFRP takviyelerinin kalitesini sağlamak için, en uygun maliyetli CFRP kumaşını seçmek için yüksek kaliteli CFRP kumaş seçmeli, tanınan markaları seçmeli ve satın alırken etrafta alışveriş yapmalısınız.

Karbon fiber malzemeleri takıldığında aşağıdaki koşullar yerine getirilmelidir:

a. Karbon fiber malzemeleri düzenlemelere göre kesilmelidir.

b. Bileşenlerin sıcaklığı, hava nemi ve yüzey nem içeriği gereksinimleri karşılıyor.

c. Primer ve maç dokunuşa kadar kuru (reçine yüzeyi sertleştirilmiş ve sertleştirilmiştir).

d. Bağlama reçinesi türü inşaat sırasında sıcaklık için uygundur. Ana ajan, sertleştirme ajanı ve sertleştirme hızlandırıcısı belirtilen orana göre doğru bir şekilde tartılmalı, konteynere koyulmalıdır ve bir karıştırıcıyla eşit bir şekilde karıştırılmalıdır. Tek seferlik karıştırma miktarı belirtilen süre içinde kullanılmalıdır.

Karbon fiber macun için kalite denetimi standartı.

a. Karbon fiber paketleri alt ve üst kaplamaya iyi impregnedir.

b. Karbon lif sıkıca bağlıdır.

c. 10mm'den fazla ve 30mm'den az çapı olan boş davullar için, metrekare başına 10'dan az nitelikli olarak kabul edilebilir; metrekare başına 10'dan fazla varsa, niteliksiz kabul edilir ve onarılması gerekir. Çapı 30 mm'den fazla olan boş davullar için, göründüğü sürece, niteliksiz kabul edilir ve onarılması gerekir.

d. Lif yönü boyunca yuvarlama uzunluğu 20cm'den az değildir, katmanlar arasındaki yuvarlamalar aynı düz çizgide olmamalıdır ve katmanlar en az 50cm'lik aşamalıdır.

e. Karbon fiber malzeme özellikleri, yapıştırma pozisyonu, uzunluk, genişlik, fiber yönü ve katman sayısı gereksinimleri karşılıyor.

5. CFRP takviye inşaatının kalitesini sağlamak

CFRP takviye malzemelerine ek olarak, CFRP yapıştırıcıları CFRP takviye yapısının kalitesini etkileyecektir. Dış çevre ve inşaat yöntemleri de CFRP takviyelerinin inşaat kalitesini etkileyecektir. CFRP takviye yapısının kalitesini sağlamak için çeşitli faktörler kapsamlı olarak göz önünde bulundurulmalıdır. Sadece bu şekilde CFRP takviye inşaatının kalitesi

Burada ihtiyacınız olan her şeyi bulabilirsiniz. Bu ürünleri denemeye güvenin, sonra büyük bir fark göreceksiniz.

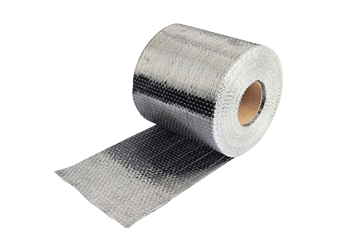

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.

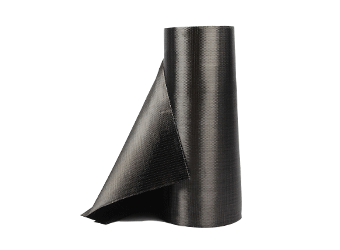

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.