Çözümler

Horse Construction, teknik destekler, dokümantasyon destekleri, ürün destekleri, yazılım destekleri, proje destekleri ile tam bir yapısal güçlendirme malzemesi yelpazesi sunar.

FRP ile Beton ve Masonry Yapılarının Güçlendirilmesi

Proje Genel Bakış

Belirli bir şehirde dört yıldızlı bir otel 1950'lerde inşa edildi ve Sovyet uzmanları tarafından tasarlanmıştır. 7 katlı tuğla beton bir yapıdır. Sismik güçlendirme olmadan tasarlanmıştır. Nisan 2006'da yapı depremlere karşı güçlendirildi ve otel binasının iç düzeni ayarlandı. Yük taşıyan duvarların bir kısmının çıkarılması ve ilgili halka kirişlerinin güçlendirilmesi gerekiyordu. Bu projedeki merdivenlerin kalınlığı çoğunlukla 60mm'dir ve çelik çubuklar 300mm aralığı olan tek bir katman olarak yapılandırılmıştır. Aynı zamanda, projenin inşaatı nispeten erken ve hizmet ömrüne ulaştı. Program gösterisi ve ekonomik ve teknik uygulanabilirlik karşılaştırmasından sonra kirişleri güçlendirmek için FRP kullanmaya karar verildi.

Malzeme özellikleri

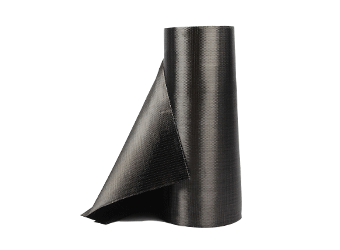

HM 12K 200gsm tek yönlü karbon lif kumaş

Ağırlık: 200g / m2

Kalınlığı: 0.111mm

Yoğunluk: 1.8g / cm³

Yönem: tek yönlü

Ambalaj: 100 metre / rulo

Genişlik: 100mm, 200mm, 300mm, 500mm veya özelleştirilecek

güçlendirme tasarımı

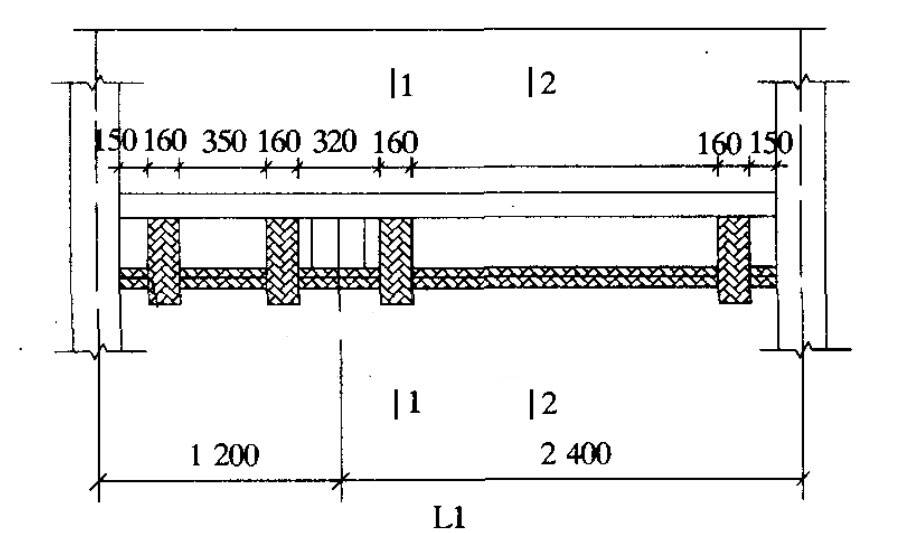

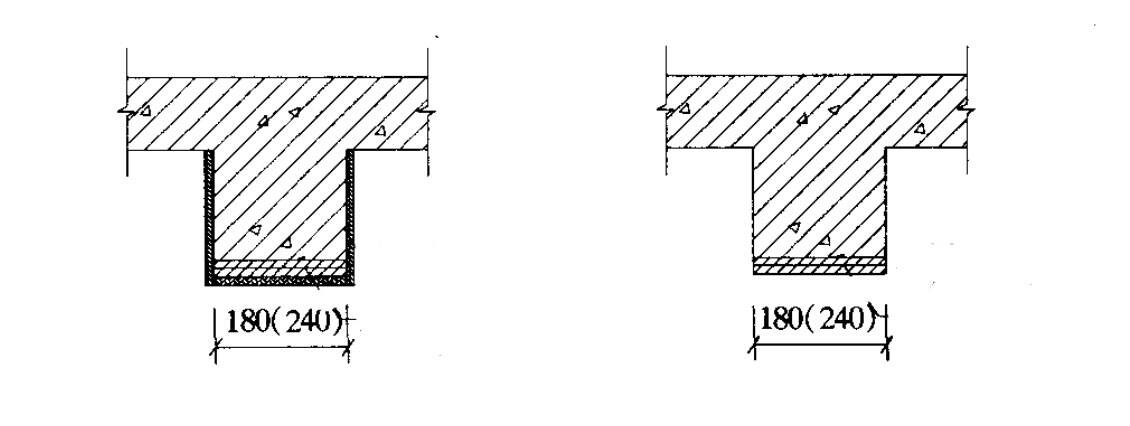

Tasarım birimi tarafından hesaplandıktan sonra ve projenin gerçek durumunu göz önüne alınarak, kirişin altındaki FRP sarmasının demirlenmesini güçlendirmek ve kirişin kesme direncini artırmak için, kirişin ucunun her tarafına 180mm genişliğindeki U şeklinde bir halka yapıştırıldı. Şekil 1'de gösterildiği gibi birincil ve ikincil kirişlerin kesişmesinin her tarafına 180mm genişliğindeki U şeklinde bir halka yapıştırın.

FRP ile inşaatın güçlendirilmesi

Boşaltma-alt katman tedavisi-alt katman reçine kaplama-düzeltme yapısı yüzey-yapıştırma FRP sarma yüzey koruması ve dekorasyonu. Projenin gerçek durumunu göz önüne alındığında, güçlendirme sırasında boşaltma yapılmalı ve yapısal çatı ve kiriş desteklenmelidir. Güçlendirirken, birinci kattan başlayın, üst kat yüzeyindeki tüm çöpleri temizleyin, kiriş tarafının tüm dekoratif yüzeyini çıkarın, cilalayın ve yapının tabanına kadar temizleyin. Birinci kat güçlendirildikten sonra, sonraki kata geçin.

FRP ile inşaat etkisi

Proje Ekim 2006'da tamamlandı ve FRP güçlendirme parçası 25 günlük bir inşaat süresine sahiptir. Tamamlandıktan sonra otel misafirleri kabul ediyor ve 5 yıldan fazla süredir kalite sorunları olmadan normal olarak çalışıyor. Ayrıca, FRP güçlendirme iyi bir inşaat etkisi, basit çalışma ve kısa inşaat süresine sahiptir ve tasarım birimleri, denetim birimleri ve sahipleri tarafından iyi kabul edilmiştir.

Burada ihtiyacınız olan her şeyi bulabilirsiniz. Bu ürünleri denemeye güvenin, sonra büyük bir fark göreceksiniz.

At karbon fiber takviyeli polimer (CFRP) laminat, HM-120CP epoksi ile dışarıdan takviye olarak yapıya bağlanan önceden kürlenmiş kompozit laminatlardır.

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.