Çözümler

Horse Construction, teknik destekler, dokümantasyon destekleri, ürün destekleri, yazılım destekleri, proje destekleri ile tam bir yapısal güçlendirme malzemesi yelpazesi sunar.

Betonda Hangi Çatlaklar Tamir Edilebilir?

Makale içeriği

1. Beton çatlaklarının nedenleri

2. Beton çatlakları nasıl onarılır?

3. Köprü çatlak onarım yöntemi

Beton çatlaklarının nedenleri

Popüler inancın aksine, beton en dayanıklı yapı malzemelerinden biridir ve birçok faktör nedeniyle çatlayabilir. Bazı durumlarda, çatlakların varlığı hoş olmayan faktörlere neden olabilir, bu nedenle kısa sürede çatlakların ortadan kaldırılması önerilir.

Ama önce, beton çatlamalarına neden olduğunu anlamanız gerekir. Bunun olmasının birkaç nedeni var:

Beton yapının dökülmesi sırasında bir hata meydana geldi;

Ağır sıcaklık düşüşü;

Küçülen binalar;

Zayıf tendonlar

Toprak genişlemesi

Tuza maruz kalma

Mekanik hasar.

Bazı durumlarda, betondaki çatlaklar yapısal bütünlük için güvenli olarak kabul edilir. Genellikle bunlar maksimum genişliği 0,4 mm olan yatay çatlaklardır. Korozif ortam beton yapısını etkilediğinde, gereksinimler 0,3 mm'ye kadar daha sıkı hale gelir.

Beton çatlakları nasıl onarılır?

Bu amaç için çeşitli malzemeler yaygın olarak kullanılır:

Çimento kum karışımı;

Sızdırmazlık

Epoksi reçine

Sıvı cam

Kendinden genişleyen çizgi.

Kompozisyonun seçimi, çatlakun genişliğini ve yerini, betonun sertleşme derecesini ve kusurun genişleme eğilimini göz önünde bulundurmalıdır.

Dikey çatlaklar durumunda, kendinden genişleyen kabloların ve listelenen kabloların en kalın karışımı avantajlıdır.

Köprü çatlak onarım yöntemi

Enjeksiyon. Bu amaçla, delikler çatlak yönünde delinir ve sonra delikler uygun bir bileşikle doldurulur. Çatlakların kenarları birbirine yapıştırılır, bu nedenle daha fazla çatlak yayılmaz.

Ateşli beton. Bu durumda, çatlakun kendisini bir tamir ajanı ile yamayın ve ardından üstüne başka bir beton karışımı katmanı püskürtün.

Mühür. Kusurlarda polimer katkı maddeleri ile dolu bir kum beton bileşimi yüzey yapışkanlığını iyileştirmek için tasarlanmıştır. Yukarıdan, sorun alanı bir sızdırmazlık katmanı tarafından yırtılır.

Beton yüzeyindeki çatlakları onarmak için uygun profesyonel aletler gereklidir.

Beton karışımının hazırlanması ve sonraki döküm tekniğini takip ederek, betondaki çatlakları önlemek mümkündür. Gelecekteki yapı büyük yükler taşıyacaksa, takviye malzemelerinden tasarruf etmek imkansızdır. Ayrıca öncelikle inşaat sahasındaki toprağı incelemeniz gerekir, böylece özellikleri gelecekte soruna neden olmaz. Beton düşük sıcaklıklarda dökülürse, beton karışımını güvenilir bir şekilde sertleştirmek için optimal sıcaklık koşulları sağlanmalıdır.

Burada ihtiyacınız olan her şeyi bulabilirsiniz. Bu ürünleri denemeye güvenin, sonra büyük bir fark göreceksiniz.

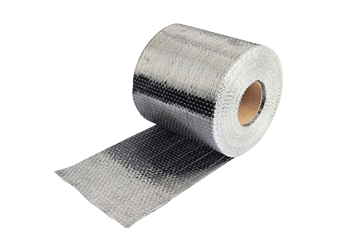

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.

At karbon fiber takviyeli polimer (CFRP) laminat, HM-120CP epoksi ile dışarıdan takviye olarak yapıya bağlanan önceden kürlenmiş kompozit laminatlardır.

Horse HM-120L beton çatlak enjeksiyon yapıştırıcısı, enjekte edilerek beton çatlaklarını onarmak için kullanılan bir epoksidir. Epoksi, yüksek nüfuz etme özelliğine sahiptir. Yapısal betondaki çatlakların düşük basınçta enjeksiyonu.