Çözümler

Horse Construction, teknik destekler, dokümantasyon destekleri, ürün destekleri, yazılım destekleri, proje destekleri ile tam bir yapısal güçlendirme malzemesi yelpazesi sunar.

Kompozit Malzemeler Kullanımıyla Beton Yapıların Takviyesi

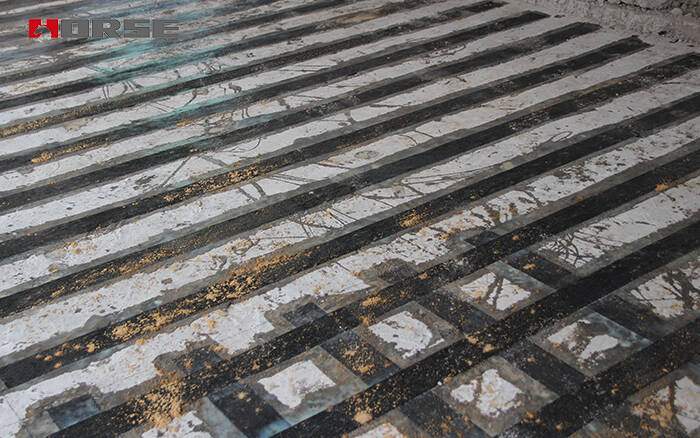

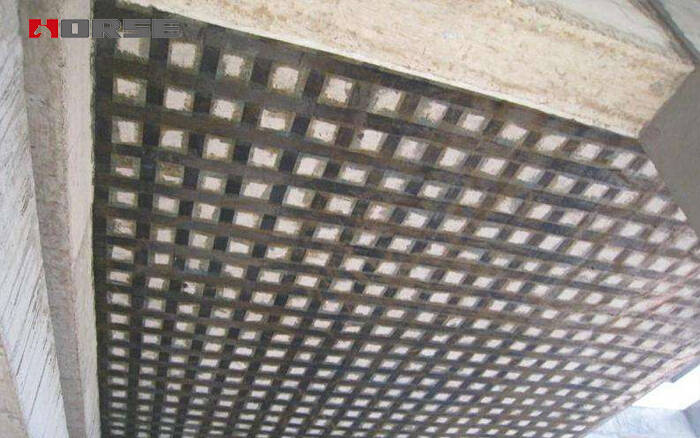

Kompozit malzemeler kullanarak beton yapıların tamiri ve takviyesi

Bu pasif takviye ilkesi, yapışkanmış dış metal levhalar kullanarak geleneksel çözüme yenilikçi bir alternatiftir:

Faydalı ömrünü uzatmak için bozulmuş, hasarlı veya tasarım veya uygulama kusurlarına maruz kalmış yapıların direncini artırmak;

Yapıyı çalışma koşullarındaki değişikliklere uyarlamak veya yük taşıma kapasitesini artırmak.

Bu teknikler şunları sağlar:

Kesme gücüne veya kirişlerin bükülmesine direncinin artması;

Çalışma yüklerinin değiştirilmesi, statik sistemin değiştirilmesi, yetersiz takviye veya taşıma kapasitesi veya hatalı uygulama durumunda yapıların güçlendirilmesi;

Standartlardaki değişikliklere uyarlamak için yapıların depreme dayanıklı takviyesi;

Beton yapıların gücünü ve sertliğini artırmak;

Direkler, sütunlar veya iskeleler;

Açılıklar veya hopper oluştururken yapıların güçlendirilmesi.

Tekniğin uygulanması, sıkı bir metodoloji, uygun iklim koşullarına (yağmurdan korunan çalışma, doğrudan güneş ışığı olmaması, dış sıcaklık 10 ila 25 ° C arasında, sınırlı nisbi nem vb.), çeşitli malzemelerin kullanım koşullarına (reçinelerin kullanım süresi vb.), güvenlik kriterlerine ve substratların hazırlanmasında büyük önlemlere uygunluk gerektirir.

Eurocode standartlarına uygun boyutlama kuralları deneysel testler, sayısal modelleme ve onarılmış ve aletlenmiş yapılar üzerine geri bildirim yoluyla geliştirilmiş ve doğrulanmıştır.

Beton yüzeyin yeterli yüzey koheziyonuna (1,5 MPa'dan büyük) ve uygun düzlüğe sahip olması gerekir, çünkü beton kompozit arayüzünün özellikleri onarımın verimliliği ve dayanıklılığı açısından özellikle önemlidir. .

Beton destek, aşağıdakiler için dikkatli bir şekilde hazırlanmalıdır:

Tatmin edici bir yüzey sertliği oluşturmak;

Yüzeyi kimyasal ve fiziksel olarak temiz ve kuru hale getirin;

Tüm yüzey ve toz, yağ, yağ izlerini çıkarın. ..

Tüm mümkün kaplamaları çıkarın;

Hiçbir kusuru (çatlaklar, delikler vb.) yoktur.

Kullanılabilecek ana teknikler şunlardır: ıslak veya kuru kum püskürtme; Yüksek basınç altında su ile yıkamak; bir elmas disk ile zımparlama.

Ürünün seçimi ve kullanılacak teknik çözüm aşağıdakilere bağlıdır:

Boyutlama gereksinimleri: kesim gücünde stres kırılması, kompozitin elastikliği modülü, davranış yorgunluğu, titreşim, şok, yangın veya deprem etkisi altında sürünmeye karşı. ..

Montajla ilgili gereksinimler: yapıştırma sırasında termal koşullar, pratik kullanım süresi, parça geometrisi vb.

Çevre koşulları (sıcaklıklar, higrometri, ultraviyole vb.), yapının izlenmesi, bakımı ve kullanımı ile bağlı dayanıklılık gereksinimleri.

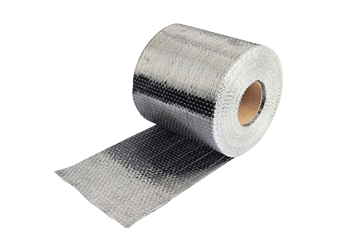

Kompozitler ya kurulum sırasında reçine ile impregnelendirilir ya da kurulumdan önce fabrikada veya yerinde önceden impregnelendirilir.

Kumaşlar veya şeritler, bir impregnasyon reçinesi aracılığıyla bir silindir kullanarak desteğe (tek veya çift yapıştırma yoluyla) yapıştırılır. Onarım, destek ve kompozit arasında oluşan herhangi bir hava baloncuğunu ortadan kaldıran ve aşırı yapışkanı çıkaran maskeleme işlemi ile sona erer. Bir kapatma katmanı, kurulduktan sonra kumaşa veya tabağa uygulanır.

Burada ihtiyacınız olan her şeyi bulabilirsiniz. Bu ürünleri denemeye güvenin, sonra büyük bir fark göreceksiniz.

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.

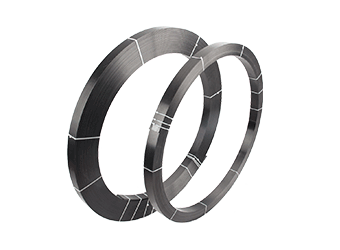

At karbon fiber takviyeli polimer (CFRP) laminat, HM-120CP epoksi ile dışarıdan takviye olarak yapıya bağlanan önceden kürlenmiş kompozit laminatlardır.

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.