Çözümler

Horse Construction, teknik destekler, dokümantasyon destekleri, ürün destekleri, yazılım destekleri, proje destekleri ile tam bir yapısal güçlendirme malzemesi yelpazesi sunar.

Rezervuardaki Karbon Fiber Güçlendirme Projesi

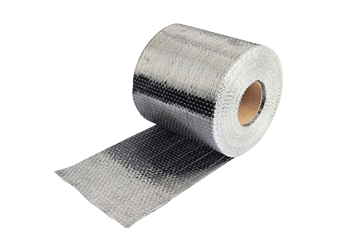

Karbon fiber kumaş takviye teknolojisi şu anda nispeten etkili ve yeni bir takviye yöntemidir. Karbon fiber kumaş çok iyi mekanik özelliklere sahiptir ve çelik çubukların yerine betonda bile kullanılabilir. Ülkemizde uzun zamandır birçok rezervuar inşa edilmiştir. Bugüne kadar, rezervuarların yapısında güçlendirilmesi gereken çeşitli sorunlar olacaktır. Karbon fiber kumaşın rezervuar takviye projelerine uygulanması konusundaki araştırmalar, iyi takviye etkisi, basit inşaat, garantili inşaat kalitesi, su geçirmez ve korozyona karşı vb. gibi avantajlara sahiptir. Bu nedenle, rezervuar takviye projesinde karbon fiber kumaşının kullanımı iyi bir etkiye sahiptir.

Karbon fiber takviyesinin avantajları aşağıdaki yönlerde somutlanır

1.1 İyi takviye etkisi

Karbon fiber kumaş iyi mekanik özelliklere sahiptir. Gücü, yüksek elastiklik modülü, hafif ağırlığı ve düşük uzunluğu çelik çubukların mekanik özelliklerinden daha iyidir. Rezervuar takviye projesinde karbon fiber kumaşının üstün performansının tam olarak kullanılması, depo yapısının taşıma kapasitesini, çatlak direncini ve esnekliğini artırabilir ve deponun takviye ve bakımı üzerinde iyi bir etkiye sahip olabilir.

1.2 Karbon fiber kumaşın basit yapısı

Rezervuar takviye projesinde karbon fiber kumaş kullanan inşaat yöntemi, büyük ölçekli inşaat ekipmanları içermeden, karbon fiber kumaşını yapay yapıştırıcılarla takviye edilmesi gereken yapıya yapıştırmaktır, inşaat süreci nispeten basittir ve diğer faktörlerden etkilenmeyecektir. Bazı özel durumlarda, rezervuar çalışmaya devam ederken güçlendirilmesi gereken yapı inşa edilebilir. Karbon fiber kumaşın inşaat prosedüründen, çalışmasının basit olduğunu, sadece karbon fiber kumaşını yapıya yapıştırın, katlandığını bekleyin ve kuvvetin gereksinimleri karşıladığını tespit edin. Normal koşullarda, inşaat sadece 2 ila 3 gün sürer.

1.3 İnşaat kalitesini garanti edebilir

Karbon fiber kumaş inşa edildiğinde, kalitesinin ana yönü yapıştırma sürecindedir. Bununla birlikte, karbon fiber kumaş esnek bir malzemedir. Yapıya yapıştırılması kolaydır ve yapıştırmanın yoğunluğunu sağlayabilir. İnşaat sırasında, sıradan işçiler, karbon fiber kumaşın yapışkanma yoğunluğunun% 95'ten fazlasına ulaşmasını sağlayabilirler, yani etkili yapışkanma alanının% 95'ten daha büyük olmasını sağlayabilirler, bu da karbon fiber kumaş güçlendirilmiş rezervuar projelerinin kalite gereksinimlerini karşılayabilir.

1.4 Karbon fiber kumaş süper su geçirmez ve korozyon önleyici etkiye sahiptir

Karbon fiber kumaş iyi bir korozyon önleyici etkiye sahiptir ve epoksi reçine bileşeni süper su geçirmez bir etkiye sahiptir. Rezervuarın inşaatı genellikle suyla temas halinde ve korozyona daha duyarlıdır ve rezervuarın inşaatında çeşitli sorunlar ortaya çıkacaktır. Tüm karbon fiber kumaş, su veya diğer aşıntıcı maddelerin yapı yüzeyine doğrudan temas etmesini önleyebilir ve böylece korozyon önleyici bir rol oynayabilir. Bu nedenle, karbon fiber su geçirmez ve korozyona karşı etkisi olmak için rezervuar takviye projelerinde kullanılmaz.

Burada ihtiyacınız olan her şeyi bulabilirsiniz. Bu ürünleri denemeye güvenin, sonra büyük bir fark göreceksiniz.

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.

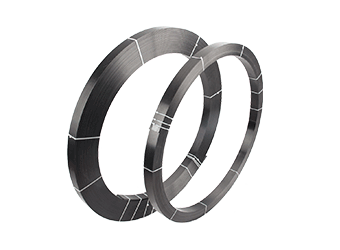

At karbon fiber takviyeli polimer (CFRP) laminat, HM-120CP epoksi ile dışarıdan takviye olarak yapıya bağlanan önceden kürlenmiş kompozit laminatlardır.