Çözümler

Horse Construction, teknik destekler, dokümantasyon destekleri, ürün destekleri, yazılım destekleri, proje destekleri ile tam bir yapısal güçlendirme malzemesi yelpazesi sunar.

Yapısal Güçlendirme için Karbon Fiber Laminat

Demirbeton yapılar genellikle hizmet ömrü boyunca performans değişiklikleri ve iyileştirilmelerle karşılaşır. Etkileyen faktörler arasında kullanımındaki değişiklikler, yeni tasarım standartları ve depremler gibi koroziv ortamlara maruz kalma nedeniyle çelik korozyonundan kaynaklanan bozulma yer almaktadır.

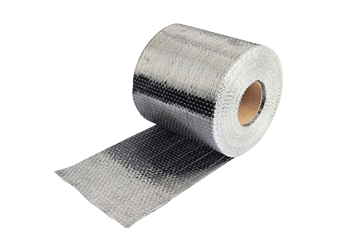

CFRP teknolojisi bu sorunları farklı ürün türleri kullanarak çözüyor. Bir tür karbon fiber kumaş, diğer tür ürün ise karbon fiber laminatdır. Yapıştırıcı ile impregnelenmiş ve otoklavda sertleştirilmiş tek yönlü karbon elyaftan yapılmıştır. Üretimde epoksi reçine impregnasyonu, malzemenin güvenilirliğini arttırır ve inşaat sahasında epoksi reçine ile karbon lifinin eşitsiz impregnasyonu fenomenini ortadan kaldırır.

Karbon fiber laminat, önceden belirlenmiş bir yönde düzenlenen, daha sonra epoksi reçine gibi malzemelerle impregnelendirilen ve katı levhalara sıkıştırılan birden fazla katmandan oluşan bir kompozit malzemedir. Çalışma prensipi, güçlendirilmesi gereken yapısal bileşenlerin yüzeyine karbon fiber laminatlarını yapıştırmak, stres altında yapısal bileşenlerin deformasyonuna ve titreşimine karşı koymak için yüksek mukavemetlerini ve sertliklerini kullanarak yapısal bileşenlerin genel performansını iyileştirmektir.

Karbon laminatları yük taşıma kapasitesini artırır ve genel bina yapılarını, endüstriyel binaları, köprüleri ve farklı malzemelerden yapılmış diğer yapıları onarabilir. Ayrıca endüstriyel ve sivil tesislerde yapılar üzerindeki operasyonel yükü arttırır. Yapının yük taşıma kapasitesini geri kazanabilir, sismik dayanıklı hale getirebilir, yüzey çatlaklarının oluşumunu sınırlayabilir ve sertliği artırabilir. Destek, duvar ve zemin enkazlarını kaldırdığınızda ve tasarım ve inşaat hatalarını düzelttiğinizde, statik planı da değiştirir.

Karbon laminatları, hafif ağırlık, korozyon direnci, mükemmel mekanik mukavemet ve sertlik gibi mükemmel performans kombinasyonlarına sahiptir ve bu da elindeki sorunları kolayca çözebilir. Kurulum süreci sırasında esnek kumaş şeklinde uygulanır ve ardından, kuvvet-ağırlık oranına sahip çok sağlam bir malzemeye dönüştürmek için reçine matrisi ile ıslanır.

Karbon laminatlarının avantajları;

Yapıya sismikliğe karşı bir bariyer sağlayın.

Karbon laminatının kurulması ve kullanımı kolaydır.

Beton yüzeylerin görünümünü iyileştirmek

Yapının dayanıklılığını artırın.

Yapının işlevsel performansını geliştirmek.

Uygulama alanı;

Endüstriyel altyapı

Köprüler ve iskeleler

Boru hattı altyapısı

bina

Burada ihtiyacınız olan her şeyi bulabilirsiniz. Bu ürünleri denemeye güvenin, sonra büyük bir fark göreceksiniz.

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.

At karbon fiber takviyeli polimer (CFRP) laminat, HM-120CP epoksi ile dışarıdan takviye olarak yapıya bağlanan önceden kürlenmiş kompozit laminatlardır.

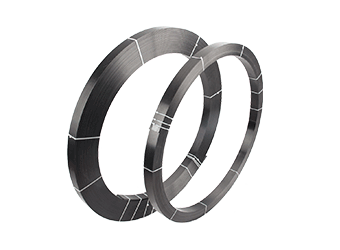

At karbon fiber takviyeli polimer (CFRP) plaka, HM-120CP epoksi ile dışarıdan takviye olarak yapıya bağlanan önceden kürlenmiş kompozit şeritlardır.