Çözümler

Horse Construction, teknik destekler, dokümantasyon destekleri, ürün destekleri, yazılım destekleri, proje destekleri ile tam bir yapısal güçlendirme malzemesi yelpazesi sunar.

Son yıllarda, karbon sarma çözümleri yapısal onarım ve takviye alanında öncü bir teknoloji olarak ortaya çıktı.

Son yıllarda, karbon sarma çözümleri yapısal onarım ve takviye alanında öncü bir teknoloji olarak ortaya çıktı. Bu makalede karbon sarma çözümlerinin neler olduğunu, neden diğer yöntemlerden üstün olduklarını, faydalarını ve uygulamalarını, uygulama sürecini, çözebilecekleri sorunları ve sundukları avantajları keşfedilir.

Karbon Sarma Çözümleri Nedir?

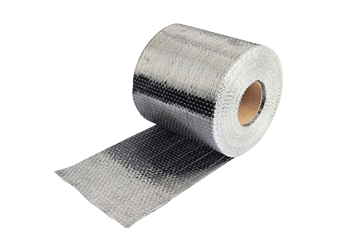

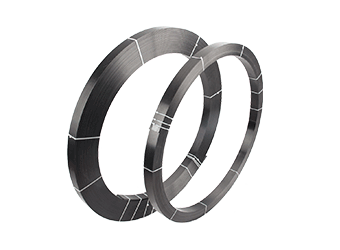

Karbon fiber güçlendirilmiş polimer (CFRP) sistemleri olarak da bilinen karbon sarma çözümleri, yapıların gücünü ve dayanıklılığını artırmak için karbon fiber levhaların veya kumaşların uygulanmasını içerir. Bu sarmalar hafif, esnektir ve mükemmel bir çekme mukavemetine sahiptir.

Karbon Sarma Çözümleri Neden Diğerlerinden Daha İyidir?

a. Üstün Mukavmet: Karbon sarma çözümleri çelik levhalar veya beton enjeksiyonları gibi geleneksel onarım yöntemlerini aşan olağanüstü çekme mukavemeti sunar. Yüksek stres seviyelerine dayanabilir ve daha fazla yapısal hasarı önleyebilirler.

b. Esneklik: Sert alternatiflerin aksine, karbon sarma çözümleri çeşitli şekiller ve yapı boyutlarına uymalarına izin veren esneklik sağlar. Bu, eğri veya düzensiz yüzeyler gibi zorlu alanlarda etkili bir takviye sağlar.

c. Korozyon Direnci: Karbon lif malzemeler korozyona son derece dayanıklıdır, bu da onları korozyon ortamlarda uygulamalar için ideal hale getirir. Çelik takviyelerden farklı olarak, karbon sarmalar zamanla bozulmaz ve daha uzun süreli onarımlara neden olur.

d. Hafif: Karbon sarmalar geleneksel alternatiflerden önemli ölçüde daha hafifdir ve yapıdaki ek yükü azaltır. Bu özellik, ağırlık dikkate alınmalarının çok önemli olduğu retrofit uygulamaları için özellikle avantajlıdır.

Karbon Sarma Çözümlerinin Faydaları:

a. Hızlı Kurulum: Karbon sarma çözümleri hızlı bir şekilde uygulanabilir, durma süresini ve yapının bozulmasını en aza indirir. Bu verimlilik özellikle zaman duyarlı onarım projelerinde faydalıdır.

b. Maliyet Etkililiği: Karbon sarma çözümleri daha yüksek ön maliyetlere sahip olsa da, uzun vadeli maliyet tasarrufu sağlarlar. Dayanıklılıkları ve uzun ömrü sık sık onarım veya değiştirme ihtiyacını azaltır ve genel maliyet azaltmasına neden olur.

c. Girişimci olmayan: Geniş bir yıkım veya kazı gerektirebilecek invaziv onarım yöntemlerinden farklı olarak, karbon sarma çözümleri girişimci değildir. Yapıya dış olarak uygulanabilir, sakinlerin bozulmasını en aza indirebilir ve binanın estetiklerini koruyabilirler.

Karbon Sarma Çözümlerinin Uygulamaları:

a. Yapısal Rehabilitasyon: Karbon sarmalar, köprüler, sütunlar, kirişler ve duvarlar gibi hasarlı veya zayıflı yapıları rehabilite etmek için yaygın olarak kullanılır. Yük taşıma kapasitesini ve yapısal bütünlüğünü geri kazanmak için etkili bir çözüm sağlarlar.

b. Sesmik Yükseltmeler: Karbon sarma çözümleri, yapıların esnekliğini ve sertliğini artırarak sismik direncini artırabilir. Bu, depremler sırasında yapısal arıza riskini azaltmaya ve genel güvenliği iyileştirmeye yardımcı olur.

c. Yeniden montaj: Mevcut yapılar, yeniden montaj amaçları için karbon sarma çözümlerinden faydalanabilir. Güncellenmiş bina kurallarına uymak veya kullanımdaki değişiklikleri karşılamak için binaları güçlendirebilirler ve uyumluluğu ve güvenliği sağlayabilirler.

Dahil:

levhalar

İskeleri

Ahşap Kağırları

İskeler

Barajlar

Köprüler

Kirişler

Ticari borular

Şaft temelleri

Kağır temelleri

Deniz duvarları

Çimento sütunları

Kalem Stokları

Su Alış ve Deşarj Sistemleri

Karbon Sarma Çözümleri Çözebilir Sorunlar:

a. Yapısal bozulma: Karbon sarma çözümleri, korozyon, beton bozulması, yorgunluk ve delaminasyon gibi yapısal bozulma ile ilgili sorunları ele alır.

b. Yük taşıma kapasitesi: Yapıların yük taşıma kapasitesini artırarak, karbon sarma çözümleri aşırı yükler veya yaşlanma nedeniyle meydana gelen yapısal arızaları önleyebilir veya onarabilir.

c. Yapısal Dayanıklılık: Karbon sarmalar, depremler, yüksek rüzgarlar veya etki olayları gibi çevresel faktörlere karşı yapıların dayanıklılığını artırır.

Burada ihtiyacınız olan her şeyi bulabilirsiniz. Bu ürünleri denemeye güvenin, sonra büyük bir fark göreceksiniz.

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.

Düşük viskoziteli, iyi emdirme, belirli tiksotropik özelliğe sahip, takviyeli bileşen yüzeyi ve elyaf ürünlerinin emdirilmesi ve yapıştırılması için kullanılır. Horse karbon fiber yapıştırıcısının görevi, elyaf ürünlerine tamamen batırılması ve elyaf ürünl

At karbon fiber takviyeli polimer (CFRP) laminat, HM-120CP epoksi ile dışarıdan takviye olarak yapıya bağlanan önceden kürlenmiş kompozit laminatlardır.