Çözümler

Horse Construction, teknik destekler, dokümantasyon destekleri, ürün destekleri, yazılım destekleri, proje destekleri ile tam bir yapısal güçlendirme malzemesi yelpazesi sunar.

FRP composite strengthening system is applicable to strengthening of reinforced concrete(RC) under bending, axial compression, large eccentric compression, small eccentric compression and tensile members. It is not suitable for reinforcement of plain concrete members or members with minimum reinforcement ratio less than the current specification.

Application

FRP composite strengthening system is applicable to strengthening of reinforced concrete(RC) under bending, axial compression, large eccentric compression, small eccentric compression and tensile members. It is not suitable for reinforcement of plain concrete members or members with minimum reinforcement ratio less than the current specification.

Requirement

The strength grade of reinforced concrete members shall not be less than C15, and the tensile bond strength of concrete surface shall not be lower than 1.5MPa.

The increase of bending capacity of normal section should not exceed 40%, and the sheet should not exceed 4 layers.

The temperature of the environment used for a long time is not more than 60 degrees.

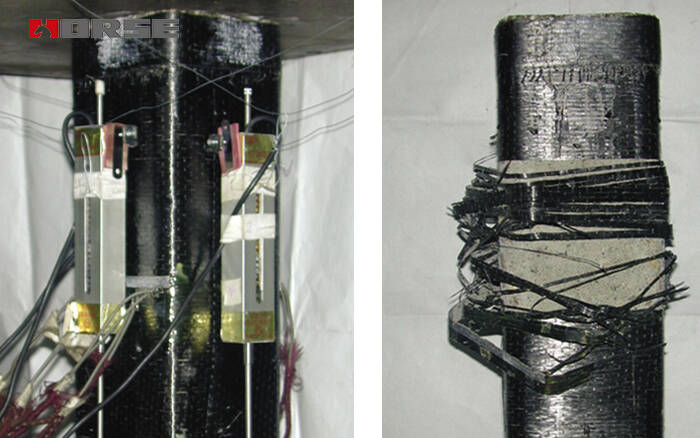

Failure characteristics

(1) sticking steel plate to yield strength or being broken.

(2) the fracture of steel plate anchorage zone and base is brittle failure.

Material requirements

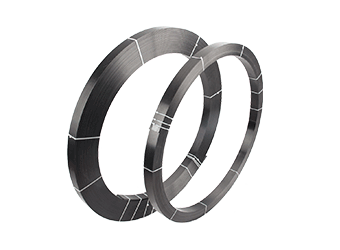

For carbon fiber reinforcement for load-bearing structure, polyacrylonitrile (PAN based) 24K or 24K should be used.

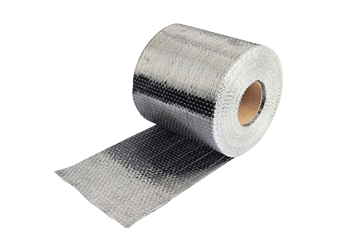

The load-bearing structure is reinforced with glass fiber, which is high strength S glass fiber or E glass fiber containing less than 0.8% must be selected. The use of A glass fiber or C glass fiber is strictly prohibited.

The adhesive for impregnating and sticking fiber composite material must be modified epoxy resin, and the unsaturated polyester resin and alkyd resin are not used in the load-bearing structure.

Method

The longitudinal reinforcement is applied to the tensile area of the beam and plate member to carry out bending reinforcement.

The beams and columns are reinforced by closed paste, U paste or side bonding.

The enclosed paste is used to reinforce the column.

Key characteristics

The influence scope of reinforcement is small, the construction speed is fast, and the process is simple.

The material is resistant to corrosion and has good durability.

The ability to tolerate late deformation is strong.

Under normal conditions, high strength of materials is difficult to play.

Burada ihtiyacınız olan her şeyi bulabilirsiniz. Bu ürünleri denemeye güvenin, sonra büyük bir fark göreceksiniz.

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.

Düşük viskoziteli, iyi emdirme, belirli tiksotropik özelliğe sahip, takviyeli bileşen yüzeyi ve elyaf ürünlerinin emdirilmesi ve yapıştırılması için kullanılır. Horse karbon fiber yapıştırıcısının görevi, elyaf ürünlerine tamamen batırılması ve elyaf ürünl

At karbon fiber takviyeli polimer (CFRP) laminat, HM-120CP epoksi ile dışarıdan takviye olarak yapıya bağlanan önceden kürlenmiş kompozit laminatlardır.