Çözümler

Horse Construction, teknik destekler, dokümantasyon destekleri, ürün destekleri, yazılım destekleri, proje destekleri ile tam bir yapısal güçlendirme malzemesi yelpazesi sunar.

Low pressure crack injection for structural crack reapir This method is suitable for repairing concrete cracks with crack width of 0.2-0.3 mm. It is to inject adhesive into cracks to improve their waterproofness and durability.

Low pressure crack injection for structural crack reapir

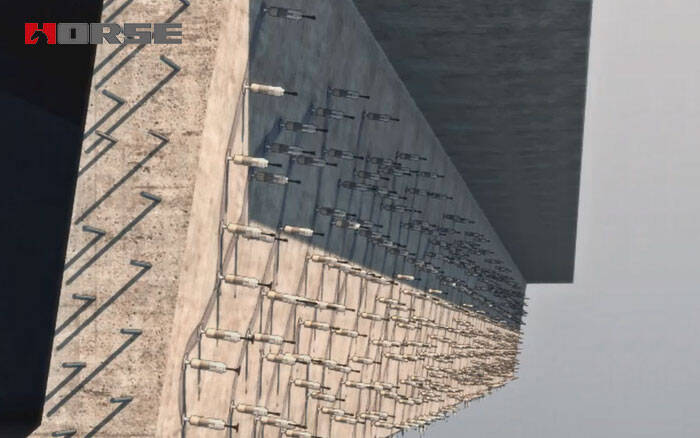

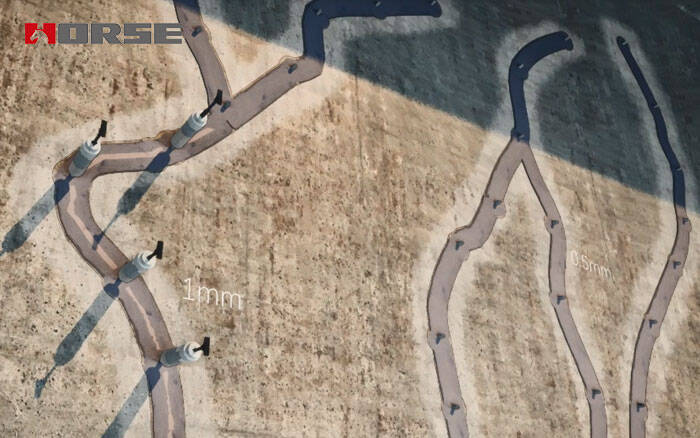

This method is suitable for repairing concrete cracks with crack width of 0.2-0.3 mm. It is to inject adhesive into cracks to improve their waterproofness and durability. For incomplete cracks, grouting method is difficult to inject slurry into the interior. When the injection pressure is too high, it is possible to expand the crack width. Therefore, at present, low pressure and low speed injection methods are widely used.

The construction process of HM 120L crack injection adhesive

Crack surface repair

First, chip away plastering of the range on each side of crack by 10cm.

Slot cracks

Sloppy along crack according to design, then polishing and cleaning it up.

Sealing ports, sealing cracks

Sealing creaks and ports with structural repairing adhesive, keep ports distance 10 to 30 cm.

Air pressurre test

When the structural repairing adhesive has cured, precedes the air pressure testing if there is leakage, see less or reinstall ports.

Mix adhesive

Mix the horse construction crack injection adhesive according to the ratio. Stir evenly and avoid any bubble.

Inject adhesive

Inhaled the adhesive with adhesive injector and inject adhesive via ports one by one. Start the second injector when adhesive overflow from one side to the other side. When crack injection adhesive has initial cured, remove injectors and ports.

Inspect quality

Level the surface with structural repairing adhesive, take the quality inspection after 7 days.

We also have the install video, plz check the link

Burada ihtiyacınız olan her şeyi bulabilirsiniz. Bu ürünleri denemeye güvenin, sonra büyük bir fark göreceksiniz.

HM-9 çatlak sızdırmazlık yapıştırıcısı, genellikle çatlak sızdırmazlık ve enjeksiyon nozulu sabitleme için dökme çatlak yapıştırıcısıyla birlikte kullanılan iki bileşenli modifiye epoksi reçine yapıştırıcısıdır.

Horse HM-120L beton çatlak enjeksiyon yapıştırıcısı, enjekte edilerek beton çatlaklarını onarmak için kullanılan bir epoksidir. Epoksi, yüksek nüfuz etme özelliğine sahiptir. Yapısal betondaki çatlakların düşük basınçta enjeksiyonu.