Çözümler

Horse Construction, teknik destekler, dokümantasyon destekleri, ürün destekleri, yazılım destekleri, proje destekleri ile tam bir yapısal güçlendirme malzemesi yelpazesi sunar.

CFRP retrofitting

Project Overview

In 2003, the coking and dust removal project of the Hangzhou Iron and Steel Coking Plant increased the top load of coke ovens 1 and 2. However, some concrete of the original load-bearing structure of No. 1 and No. 2 coke ovens has been damaged and chamfered, the steel bars are exposed and corroded, and some concrete components have cracks, carbonization, hollowing and looseness. According to the structural reliability testing and appraisal report, Hangzhou Iron and Steel decided to strengthen the end table of No. 1 and No. 2 coke ovens, the main beam of the inquiry platform and the beam of the coal loading car, the corbel and the operating side beam of the coke side.

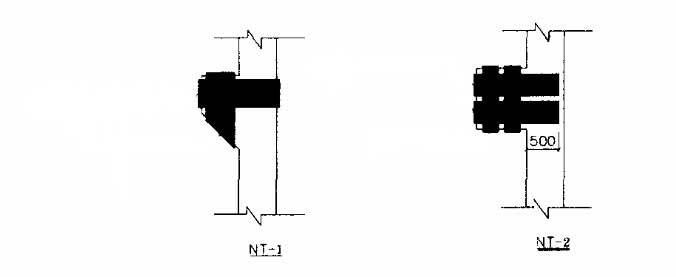

Structural strengthening method

In the design, the CFRP retrofitting method was selected to reinforce the No. 1 and No. 2 coke ovens of Hanggang. The advantage of this method is that the construction is fast, only a small amount of wet work such as plastering is on site, which has little impact on production, and after curing, there is no significant impact on the appearance of the original structure and the original headroom. Corrosion and turbidity resistance, moisture resistance, almost no increase in structure weight, durability, and low maintenance costs

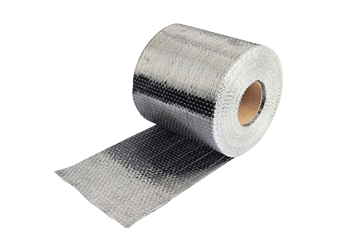

Structural einforcement material

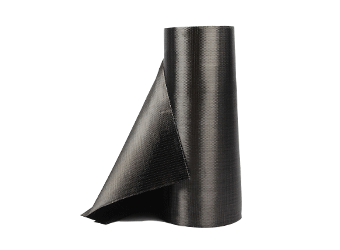

The reinforcing material is a unidirectional carbon fiber fabric produced by Horse Construction Company. The fiber specification is 300g/m2, the thickness is 0.167mm, and the tensile strength is 3750MPa. The adhesive used is a special adhesive for carbon fiber (epoxy resin), the use temperature is not less than 70 degrees Celsius, and the service life is greater than or equal to 30 years.

Application effect

The application of the CFRP retrofitting method in the coking plant fully demonstrates its advantages of high strength, light weight, corrosion resistance, simple construction and little impact on space. Since the project was completed and used in August 2003, it has ensured the normal use of production and received good results.

Burada ihtiyacınız olan her şeyi bulabilirsiniz. Bu ürünleri denemeye güvenin, sonra büyük bir fark göreceksiniz.

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.

Düşük viskoziteli, iyi emdirme, belirli tiksotropik özelliğe sahip, takviyeli bileşen yüzeyi ve elyaf ürünlerinin emdirilmesi ve yapıştırılması için kullanılır. Horse karbon fiber yapıştırıcısının görevi, elyaf ürünlerine tamamen batırılması ve elyaf ürünl

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.