Çözümler

Horse Construction, teknik destekler, dokümantasyon destekleri, ürün destekleri, yazılım destekleri, proje destekleri ile tam bir yapısal güçlendirme malzemesi yelpazesi sunar.

Carbon fiber strengthening

Project Overview

A residential building at the bottom of the building is a 6-story bottom-frame house with a rectangular plan, a length of 42.3 m and a width of 14.6 m, and a total construction area of approximately 3 903.72 square meters. The first floor, the second floor is commercial, and the third to sixth floors are residential. The total height of the house is 20.1 m. The height of layer 1 is 3.9 m, the height of layer 2 is 3.7 m, and the height of layers 3-6 is 2.8 m.

The residential building uses a reinforced concrete strip foundation under the column. The frame beams and columns of the first and second floors are made of cast-in-place reinforced concrete, the concrete strength level is C20, and the floor slab is C30. The 3rd to 6th floors are masonry structures, using MU10 concrete porous bricks, M10 mixed mortar, and external walls. It is 370 mm thick and the inner wall is 240 mm thick. The floor slab is cast-in-place reinforced concrete, except for the local slab thickness of 120 mm, the rest of the slab thickness is 100 mm. The house uses cast-in-place reinforced concrete slab stairs. The roof is sintered clay tile roof.

The residential building was completed in June 2008. In the main experience collection process, the steel frame detector found that the bottom frame part 1 floor, 2 floors KZ2a (corner column), KZ2 (stairway to the middle) a total of 16 frame column stirrups are not encrypted according to the drawing requirements full height.

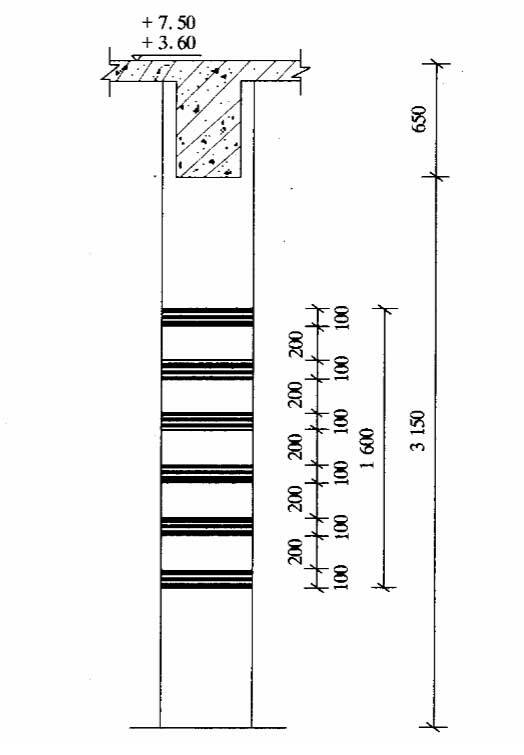

In order to ensure the shear resistance of the frame columns and meet the design requirements of the construction drawings, it is necessary to take reinforcement measures for a total of 16 frame columns on the first and second floors of the residential building at the bottom. After on-site field investigation, referring to relevant specifications and technical data, combined with the actual situation, it was decided to adopt the reinforcement technology of pasting carbon fiber hoop + crimping steel plate to carry out seismic reinforcement of the frame column.

Design plan and materials

Because the concrete shear wall is installed on the side of the frame column, it is difficult to realize the carbon fiber sealing hoop, so the technology of sticking the carbon fiber hoop + crimping steel plate is adopted for seismic reinforcement.

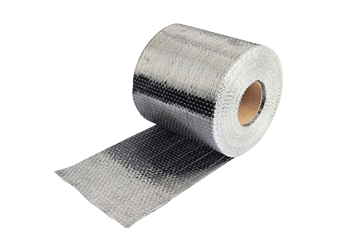

The reinforcing material is a unidirectional carbon fiber fabric produced by Horse Construction Company. The fiber specification is 300g/m2, the thickness is 0.167mm, and the tensile strength is 3750MPa. The adhesive used is a special adhesive for carbon fiber (epoxy resin), the use temperature is not less than 70 degrees Celsius, and the service life is greater than or equal to 30 years.

Conclusion

Through the use of carbon fiber reinforcement, it can effectively improve the shear resistance of the frame column and meet the design requirements of the original drawings.

Burada ihtiyacınız olan her şeyi bulabilirsiniz. Bu ürünleri denemeye güvenin, sonra büyük bir fark göreceksiniz.

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.

Düşük viskoziteli, iyi emdirme, belirli tiksotropik özelliğe sahip, takviyeli bileşen yüzeyi ve elyaf ürünlerinin emdirilmesi ve yapıştırılması için kullanılır. Horse karbon fiber yapıştırıcısının görevi, elyaf ürünlerine tamamen batırılması ve elyaf ürünl

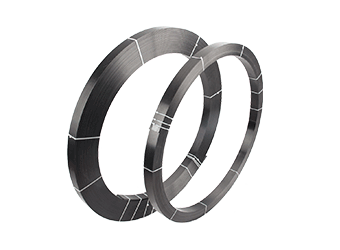

At karbon fiber takviyeli polimer (CFRP) laminat, HM-120CP epoksi ile dışarıdan takviye olarak yapıya bağlanan önceden kürlenmiş kompozit laminatlardır.