Çözümler

Horse Construction, teknik destekler, dokümantasyon destekleri, ürün destekleri, yazılım destekleri, proje destekleri ile tam bir yapısal güçlendirme malzemesi yelpazesi sunar.

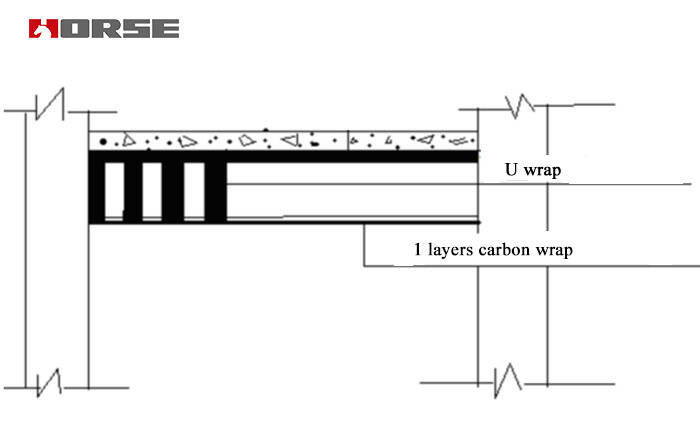

beam strengthening with unidirectional carbon fiber sheet

The basic design principles and general regulations of reinforced concrete beams with unidirectional carbon fiber sheets

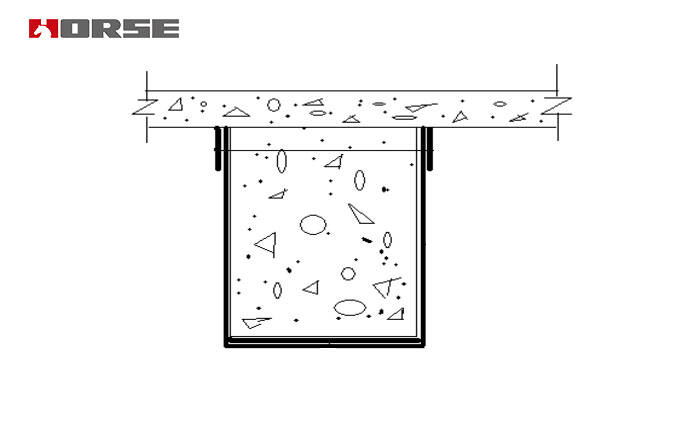

(1) When using carbon fiber sheet to reinforce and repair the concrete structure, the carbon fiber sheet is pasted on the surface of the component through a matching bonding material. The carbon fiber sheet should be made to withstand tensile stress and coordinate with the deformation of the concrete to bear the force together.

(2) The main forms of carbon fiber sheet used for reinforcement of concrete beams are:

1) Paste a carbon fiber sheet on the tensile surface of the beam member for bending reinforcement, and the fiber direction should be consistent with the axial direction of the member.

2) Adopt closed pasting, u-shaped pasting or side pasting fiber strips to strengthen beam members under shear, and the fiber direction should be perpendicular to the member axis.

(3) When sticking carbon fiber sheets to strengthen and repair the concrete beams, the limit state design method based on probability theory should be used to calculate the bearing capacity limit state and normal service limit state according to the current relevant national standards.

Rebar and concrete materials should determine the corresponding material strength design indicators according to the actual strength obtained by structural testing and according to the current relevant national regulations. According to its design strength grade, the corresponding material strength design index can be adopted according to the current relevant national regulations.

Carbon fiber sheet should be based on the strain reached in the corresponding limit state of the component, and the stress in the limit state should be determined according to the linear elastic stress-strain relationship.

(4) The ultimate tensile strength of carbon fiber material is the standard value of the tensile strength of the material provided by the manufacturer. The ultimate tensile strain of carbon fiber material is its ultimate tensile strength divided by the modulus of elasticity.

(5) To ensure the reliability of the structure after reinforcement and repair. So that the structure or component does not cause serious damage in the case of carbon fiber sheet reinforcement and repair failure.

(6) When using pasted carbon fiber sheets to reinforce and repair structures or components, consideration should be given to the possible impact on other components or other properties of the structure when the load or structural system changes after reinforcement.

(7) When using pasted carbon fiber sheets for structural reinforcement and repair, the load on the structure should be removed as much as possible. When the reinforcement cannot be completely unloaded, the influence of the secondary force on the structure should be considered.

(8) In bending reinforcement and shear reinforcement, the actual concrete strength grade of the reinforced concrete structure and components should not be lower than C15.

Burada ihtiyacınız olan her şeyi bulabilirsiniz. Bu ürünleri denemeye güvenin, sonra büyük bir fark göreceksiniz.

Düşük viskoziteli, iyi emdirme, belirli tiksotropik özelliğe sahip, takviyeli bileşen yüzeyi ve elyaf ürünlerinin emdirilmesi ve yapıştırılması için kullanılır. Horse karbon fiber yapıştırıcısının görevi, elyaf ürünlerine tamamen batırılması ve elyaf ürünl

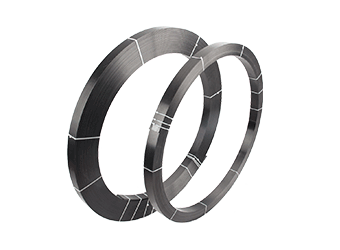

At karbon fiber takviyeli polimer (CFRP) laminat, HM-120CP epoksi ile dışarıdan takviye olarak yapıya bağlanan önceden kürlenmiş kompozit laminatlardır.

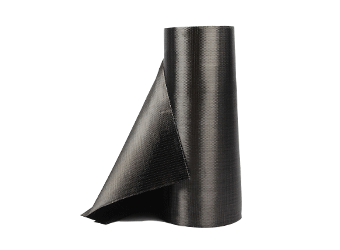

Horse Construction'ın karbon fiberi, binalar, köprüler, otoyollar, demiryolları, tüneller, iskeleler ve sivil havaalanlarındaki beton, duvarcılık, çelik ve ahşap alt tabakaların yapısal güçlendirilmesi, onarımı ve yenilenmesi içindir.